Bơm Công Nghiệp

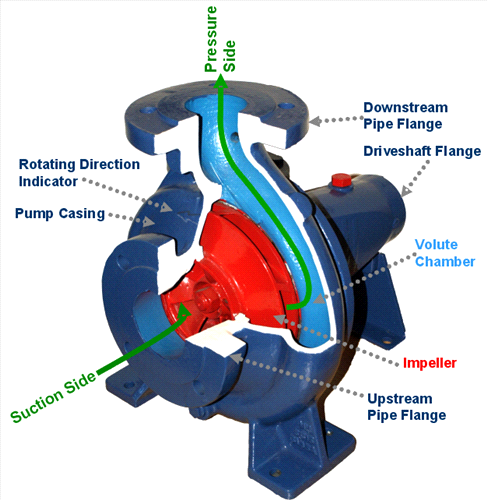

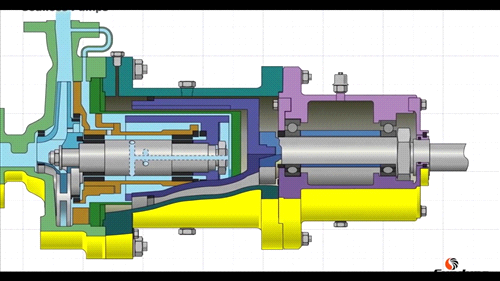

Bơm Ly Tâm

Máy bơm ly tâm được sử dụng để vận chuyển chất lỏng bằng cách chuyển đổi động năng quay thành năng lượng thủy động lực học của dòng chất lỏng. Năng lượng quay thường đến từ động cơ hoặc động cơ điện. Chúng là một phân nhóm của máy móc tuabin hấp thụ công việc đối xứng trục động. [1] Chất lỏng đi vào bánh công tác của máy bơm dọc theo hoặc gần trục quay và được tăng tốc bởi bánh công tác, chảy hướng tâm ra ngoài vào bộ khuếch tán hoặc buồng bay hơi (vỏ), từ đó nó thoát ra ngoài. Các ứng dụng phổ biến bao gồm bơm nước, nước thải, nông nghiệp, dầu khí và hóa dầu. Máy bơm ly tâm thường được chọn vì khả năng lưu lượng cao, khả năng tương thích dung dịch mài mòn, khả năng trộn lẫn, cũng như kỹ thuật tương đối đơn giản của chúng.

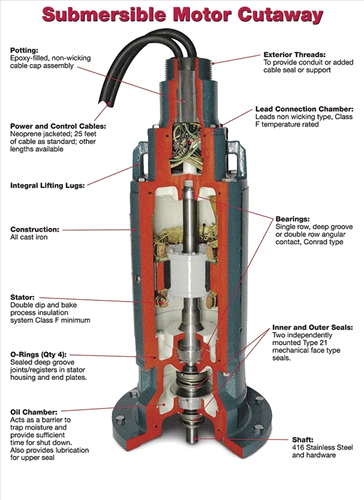

Bơm Chìm

Máy bơm chìm hay còn gọi là máy bơm chìm dùng điện là loại máy bơm có thể đặt chìm hoàn toàn trong nước. Động cơ được làm kín và gắn chặt với thân máy bơm.

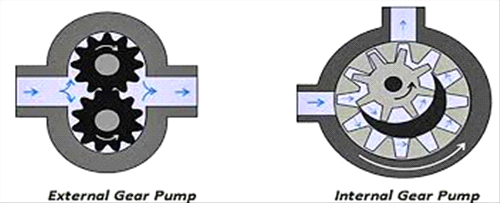

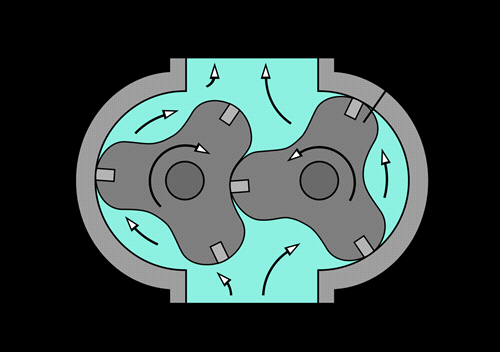

Bơm Bánh Răng

Bơm bánh răng là máy bơm quay có chuyển vị tích cực vận chuyển chất lỏng sử dụng bánh răng quay . Chúng hoạt động thông qua việc sử dụng hai hoặc nhiều bánh răng bên trong tạo ra áp suất chân không, đẩy các chất lỏng. Bơm bánh răng là máy bơm nhỏ gọn, áp suất cao cung cấp dòng chảy chất lỏng không đổi so với máy bơm màng đôi và máy bơm thẩm thấu. Chúng thích hợp nhất cho các ứng dụng có độ nhớt cao như dầu, chất dẻo, sơn, chất kết dính, hoặc xà phòng.

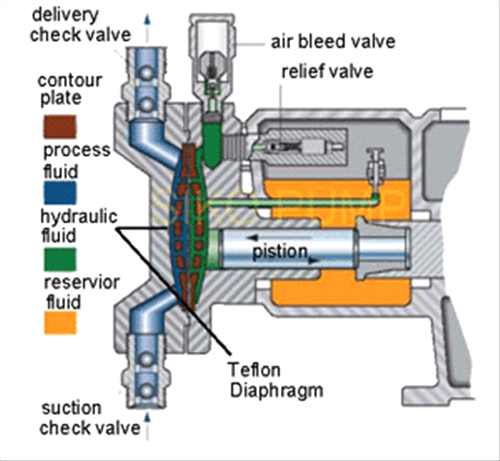

Bơm Định Lượng

Máy bơm định lượng là loại máy bơm hóa chất có thể tích lưu lượng thấp, có thể điều khiển lưu lượng tự động hoặc bằng tay tùy theo yêu cầu công việc cần áp dụng. Đặc biệt độ chính xác của bơm rất cao và có thể bơm nhiều loại hóa chất khác nhau như: axít, bazo, chất ăn mòn cao hoặc chất có độ sệt, … Vật liệu cấu tạo nên bơm định lượng thường được làm bằng nhựa PVC, PP....màng bơm là màng teflon, đây là những vật liệu chịu được hầu hết các hoá chất.

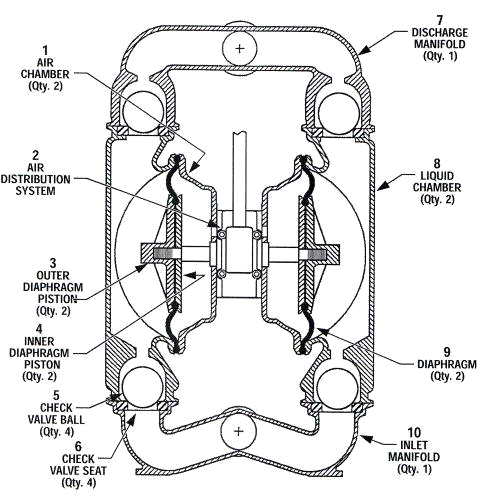

Bơm Màng Khí Nén

Máy bơm màng khí nén còn có tên gọi khác là máy bơm màng hóa chất, là loại máy bơm chuyên dùng để bơm hóa chất, thực phẩm, với nguyên lý hoạt động là sự kết hợp của màng bơm làm bằng chất liệu cao su, nhựa dẻo chuyển động qua lại bên trong đầu bơm và các viên bi đóng vai trò là van khóa. Trong đó, nhờ tác dụng của khí nén, hoặc động cơ điện mà màng bơm có thể chuyển động qua lại. Nói cách khác, máy bơm màng khí nén là sự kết hợp của máy bơm màng và máy bơm khí nén.

Bơm Từ Tính

Bơm dẫn động từ là loại bơm ly tâm không có thiết bị làm kín (sealess pump). Bộ phận nam châm ngoài gắn trục bơm sẽ truyền lực truyền động cho nam châm trong gắn với cánh bơm và từ đó, cánh bơm quay để đẩy chất lỏng. Nam châm bên ngoài và bên trong được tách rời nhau.

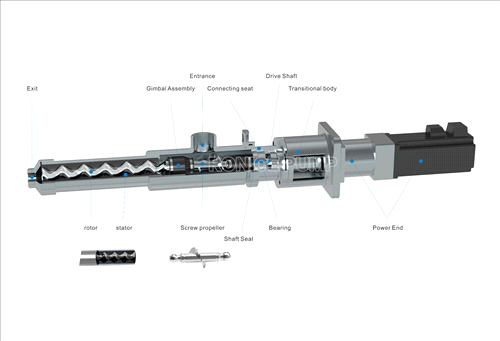

Bơm Trục Vít

Máy bơm trục vít còn có tên tiếng anh là Progessive cavity pump hay còn gọi là Screw pump, đối với những kỹ sư hay những người làm kỹ thuật thường gọi tên khác là máy bơm ruột gà. Máy bơm trục vít có tên là máy bơm ruột gà bởi vì bộ phận giúp lưu chuyển nước là một trục xoắn ốc nhìn tương tự như một chiếc ruột gà bị cắt dọc. Thành phần chính cấu thành nên máy bơm trục vít bao gồm: phốt, trục, rotor và stator.

Bơm Cánh Gạt

Máy bơm cánh gạt là một loại máy bơm dịch chuyển tích cực. Nó tương tự như một máy bơm bánh răng ngoại trừ các thùy được thiết kế để gần như gặp nhau, thay vì chạm và quay lẫn nhau.

Copyright © 2021 Hoang Tam Company Limited. All Rights Reserved.

.png)